If you have come directly to this

page via a search engine, you may choose to start at the beginning

and go to the SPEC Distribution International

Inc. Home Page for information on, speciality industrial aviation cleaning, polishing

& buffing products, techniques, & buffing equipment. To see the next

page, go to the bottom of this page and link.

SPEC Distribution

International Inc.

Specializing in supplying

the Aviation Industry Since 1989.

Welcome to our page of Interesting Pictures.

Although our main business is

supplying the commercial aviation market, we get many requests

from regular individuals wishing to restore various objects. Below

you will see a few of the many pictures we receive. All the pictures

on the page are examples of what can be accomplished using PROPER

polishing products and techniques. There is nothing magical about

the results other than they were achieved in the least amount

of time with the best possible results. Some are taken by us,

but most are pictures sent by satisfied customers. We hope you

enjoy, after all, "A picture

is worth a thousand words".

Please Note: There are a fair

number of pictures on this page , therefore, for those poor souls

with only a regular phone line modem, it may take a while to load,

(approximately 6 -8 minutes @56K) There are still some out there!. Please stick with us. I think you'll find it worth the wait.

As pictured on

our HOME page, above is proof of what can be done when one wants

to do it. On the left is a picture of "SWIFTY" the day

Francois picked her up and brought her to her new home. That was

in 1986. The pic to the right and below is how "SWIFTY"

now looks. Remember "SWIFTY" is now in her late 60's.

(Francois is not quite as old, but almost as well preserved).

Francois and "SWIFTY" are both pretty unique and they

both have an extraordinary story to tell. Click

here to link to that story. Check it

out, it's well worth the trip.

"SWIFTY"

at play with David Smith's PITTS "S1"

"SWIFTY"

at play with David Smith's PITTS "S1"

Plexiglas® properly reconditioned

with a SPEC™ Model "SA" "DRUM" type buffer. (courtesy SKYWAVE

Polishing (formerly California Custom Cleaning)

Plexiglas® properly reconditioned

with a SPEC™ Model "SA" "DRUM" type buffer. (courtesy SKYWAVE

Polishing (formerly California Custom Cleaning)

Shown below, is a series of pictures of

a particular job that was (and continues to be) rather special.

This Lockheed 10A "CF-TCC" belongs to Air Canada

and has been lovingly restored to her original condition as when

purchased from Lockheed by Trans Canada Airlines in 1939. This

particular aircraft originally belonged toTrans Canada Airlines,

(now Air Canada) and is the first passenger carrying airplane

in Canada. (This is the same model and only a few serial numbers

away from the aircraft Amelia Earhart dissapeared in.) This aircraft

is currently flown as a promotional tool, primarily in a program

Air Canada runs, called "Dreams Take Flight". This program

takes terminally ill children and their families, on an adventureous

"Flight of a lifetime". It is seen regularly at air

shows across Canada & the United States.We were originally called

in 1997 to see if we could help in the restoration of the exterior

skin itself. It is very important to note, the skin on this

aircraft is ORIGINAL, (not only that, but it has been

painted and stripped, on at least 4 separate occassions, according

to the logs). Many aircraft of this era, that have been restored

to original condition, have been "re skinned" then polished,

as part of the restoration process.This Lockheed 10A is a true

testament to the products, methods & techniques we provide.

The work on maintaining the skin on this aircraft, is done annually,

and is shared by California Custom Cleaning, (in Toronto, Ontario,)

& Glo Wing Aircraft Detailing (in British Columbia) and AIR

CANADA volunteers, depending on where Air Canada feels it is more

convenient to have the aircraft done.

Above:Before and After

Above:Before and After

Below:Part way done. note: polishing right over registration letters

with no adverse affect

The above pictures gives a pretty good idea of the

square footage to be polished

The above pictures gives a pretty good idea of the

square footage to be polished

Above:An excellent reflection & pretty good depth of image for a

60+ year old skin.

Above:An excellent reflection & pretty good depth of image for a

60+ year old skin.

The above picture shows the "non destructive"

polishing capabilities, on different materials, using "DRUM"

type equipment, and proper polishes, & techniques. This "Trans

Canada Airlines" symbol was "hand painted"on the

nose. It did not have to be covered or taped off, during

the polishing process.

A beautiful "Queen" brings back an era past.

A beautiful "Queen" brings back an era past.

The AIR CANADA Lockheed 10A "CF-TCC" in

the pictures above, has been polished by SKYWAVE Polishing

VIA Rail, Canada's

passenger rail operator, discovers an efficient, inexpensive way

to restore the Lexan™ windows of their Trans Continental

"Observation" cars. Work was done by SKYWAVE Polishingusing SPEC Machines™ pneumatic "DRUM" type

polishers and ROLITE™ GP266 "Pre-Polish, followed

by ROLITE™ AP300 , and finished by ROLITE™Polish / Sealant. These cars were built in the mid 50's. The windows

in question are between 20 and 30 years old. The original glass

windows were replaced by LEXAN panels between the mid 60's and

late 70's.

The results are pretty "CLEAR"

The results are pretty "CLEAR"

A vintage "Beech 18" belonging

to the College Edouard Monpetit, an aircraft maintenance

engineering college in Montreal, Quebec, Canada.

A vintage "Beech 18" belonging

to the College Edouard Monpetit, an aircraft maintenance

engineering college in Montreal, Quebec, Canada.

The 2 pics above are of a beautiful Grumman "GOOSE".

The owner was rather choosy about "having someone grind away" on

his rather rare and expensive classic aircraft. He chose, (wisely

I might add), California Custom Cleaning to do the job. I think

the results are pretty self explaining. Courtesy SKYWAVE Polishing

(formerly California Custom Cleaning) Note:

the props as well.

The 2 pics above are of a beautiful Grumman "GOOSE".

The owner was rather choosy about "having someone grind away" on

his rather rare and expensive classic aircraft. He chose, (wisely

I might add), California Custom Cleaning to do the job. I think

the results are pretty self explaining. Courtesy SKYWAVE Polishing

(formerly California Custom Cleaning) Note:

the props as well.

BELOW are some interesting pictures from Mr. Bill Pidlynsy, who runs a sucessful contract polishing company out of Barrie, Ontario, Canada. Bill spent many years at McDonnell Douglas Canada, polishing wing and fuselage assemblies. This is to say, he obviously has the proper qualifications for polishing things like Airstream® trailers and such.

ABOVE: Work on some aircraft wing parts and using a

large "DRUM" type pneumatic polisher.

BELOW: Some current "restoration" projects

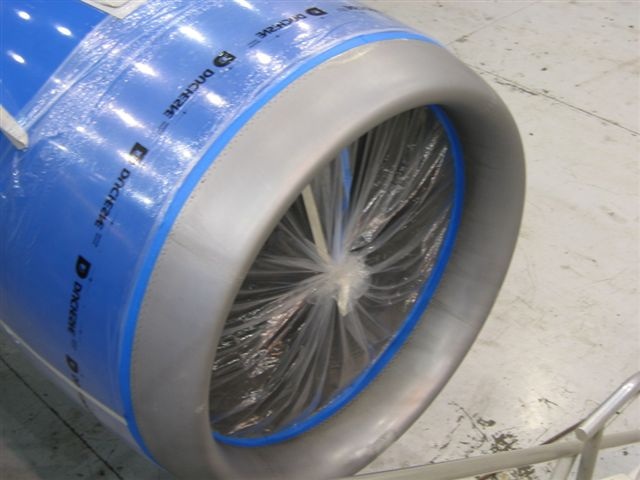

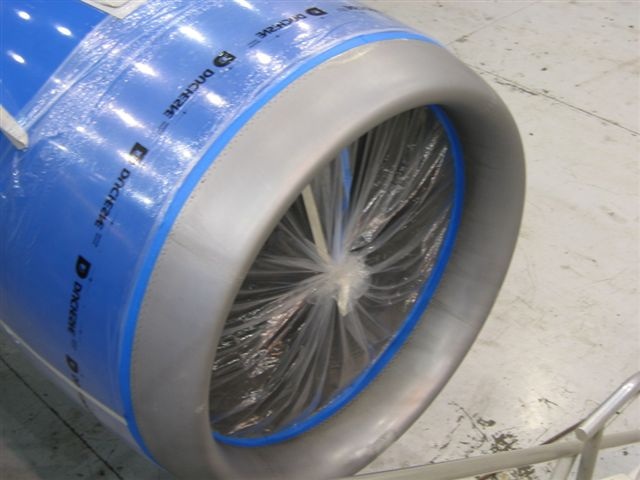

Below you will find

a series of pictures taken during the rework of the "Engine

Inlet Nose Rings" on a Boeing 767. What is interesting is

the anodized finish was completely removed as the

operator requested a conversion to a "POLISHED"finish. The transition was acomplished in 5 steps utilizing MIRKA™

"ROYAL™ & ABRALON™ Abrasive products, MATCHLESS™

paste "Cutting" compounds, and finished using ROLITE™

polishes with "DRUM" type polishing machines. (Of

special note: Although the "ANODIZED" finish is highly

"corrosion resistant" there is evidence of some inherent

problems with "stress fracturing" of the aluminum substrate,

in some instances. These fractures or cracks can often be difficult

to detect, being "hidden" by the "Anodized"

layer. The now bare or "raw" aluminum, (although in

this case the aluminum is "Alclad") is now consideribly

less resistant to corrosion. The solution is very simple. A quick,

"quarterly" light buff up, with an "annual,"

regular buff or polishing. This will virtually eliminate any chance

of corrosion & errosion.)

(Courtesy Techni-Air, Montreal,

Quebec, Canada.)

Above - BEFORE.

Below - DURING. (Note:

Clarity of reflection of the hand.)

Compare the "BEFORE"

with "ANODIZED" finish to the "AFTER" with

ANODIZING removed and converted to a "POLISHED" finish.

AFTER

The MALAYSIAN PROJECT

Below is a selection of pictures from

when I went to Malaysia in March, 2006 to train the people from

ITG (Integrated Gas & Petroleum, the tank builders) on how

to polish their tankers. The specification called for a "Polished

Finish" No Paint, only Decals allowed for Identification. (This was for

weight savings and for technical reasons due to the new alloy

in use.)

We experienced some interesting challenges. Firstly, the tank

was polished from "raw un-polished" material. The material

was a newly developed alloy by Alcan™ (France), called XTRAL

728™, which, as we found, is an extremely "hard"

aluminum alloy. We also had a serious problem with surface corrosion,

as the tank arrived from China, after spending 3 weeks on the

deck of a cargo ship in the Indian Ocean. All that being said,

the entire job was accomplished in 5 days with one SPEC Model

"SA" DRUM polisher with 1 operator & one SPEC "DETAILER"

(for corrosion removal), 5 lbs Matchless AV-20, 3lbs ROLITE AP300

& 1/2 gal ROLITE Polish Sealant (to wipe down), all while

the tank was being assembled by about 30 workers and technicians.

The results, I think, speak for themselves. In fact, the Malaysian

Road authorities wanted subsequent units to, "notbe", as "reflective" as this unit, as they felt

it would be a distraction on the road. As a note of interest,

this is the largest tanker unit ever allowed on the roads of Malaysia.

This unit was the prototype. ITG has subsequently received orders,

for 20 more.

Delivered from China (Note: Surface Corrosion from SALT water condensation) After polishing, before assembly

SPEC 1300B "DETAILER" with cotton wheels used for "RAPID" corrosion removal SPEC "SA" in use

SPEC "SA" with SH2X Extension handle on Bulkhead.

SPEC "SA" in use.

Decals being applied, (Surface had to be wiped down with solvent

first)

Assembling on chassis

Prior to final Inspection by Exxon Mobil Technical personnel

The Finished Product.

The Finished Product.

BELOW are pictures of a "repair" gone wrong. Am not sure of the full story, other than a certified maintenance engineer from an un-mentioned certified FBO in Switzerland, was directed to repair some foreign object damage on the leading edge. The repair went from bad to worse. Our client, Contrail GMBH was called in to repair the repair. The pictures below tell the story. There are actually about 50 pictures from this particular job. What you see below is the "readers digest version". If you would like to see some of the others, please contact me. (Be forwarned, they are not pretty and are only for those with a strong stomach or a great sense of humour.)

That's ALL for now Folks! You can get back to the SPEC Home

page by clicking Here!

For more information or to place an order, E-mail to: Spec Distribution International Inc.

Spec Distribution International Inc.

(Please put: Polishing Information Request, in the subject line.

It helps weed out the TONS of

spam we get.)

or telephone 001 (450) 458-2304 (Eastern Standard North

American Time)